You can count on our support worldwide! No matter where you are located, your satisfaction is our top priority.

At the Dreisbach site in the Westerwald region of Germany, approximately 100 HAAS employees take care of your needs. Worldwide, more than 20 expert HAAS partners are also available to provide you with professional advice, and our service team is mobile and always on the road for you.

If you can not find a suitable contact person for your country, please do not hesitate to contact our internal sales staff!

Phone: +49 2661 9865-0

sales@haas-recycling.de

Sales partnership with HAAS – a common opportunity for growth

HAAS Recycling-Systems is a well-known specialist for machinery and equipment in the recycling industry.

Waste contains valuable resources that can benefit our environment and future. By recycling used materials, we jointly reduce the need for natural raw materials, minimise environmental pollution and promote the economical use of energy.

Global distributors who live our values of quality and service strengthen our network.

Would you like to become our new sales partner?

Together we can contribute to nature and our future by using these valuable resources!

The recycling of used materials reduces the daily need for natural resources. Waste and environmental pollution are reduced and the saving of energy is promoted.

We are an acknowledged machine and plant specialist for the recycling industry and attach the utmost importance to quality and service for our machines!

We appreciate distributors who share our values of quality and service as they strengthen our global network. If you are interested in joining us as a HAAS sales partner in your region, we look forward to getting to know you.

Germany

- ZIP-Code 0, 10-17

HAAS Recycling-Systems

sales@haas-recycling.de

- Phone+49 (0)2661 9865-0

- AddressUnter den Weiden 6

56472 Dreisbach

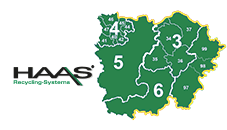

- ZIP-Code 34-37, 40-47, 5, 6, 97-99

Anna-Lena Leber

anna-lena.leber@haas-recycling.de

HAAS Recycling-Systems- Phone+49 (0)2661 9865-0

- AddressUnter den Weiden 6

56472 Dreisbach

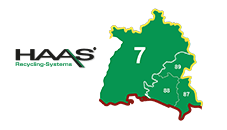

- ZIP-Code 7, 87-89

Steffen Heymann

steffen.heymann@haas-recycling.de

HAAS Recycling-Systems- Phone+49 (0)7575 209354

- Cell+49 (0)171 7932677

- AddressField office

Anton Gabele Strasse 7

88605 Meßkirch

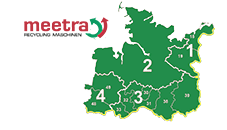

- ZIP-Code 18-19,2, 30-33, 38-39, 48-49

meetra Recycling Maschinen

info@meetra-recycling.de

Dietmar Meenken- Webwww.meetra-recycling.de

- Phone+49 (0)4407 922269

- AddressRheinstraße 14

26203 Wardenburg/Littel

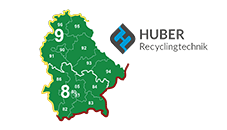

- ZIP-Code 80-86, 90-96

Huber Recyclingtechnik GmbH

j.huber@huber-recyclingtechnik.at

Jürgen Huber- Webwww.huber-recyclingtechnik.at

- Cell+43 664 1257380

- AddressGeorg Bannert-Straße 21 / Top 4

A-2442 Unterwaltersdorf

Europe

- Austria

Huber Recyclingtechnik GmbH

j.huber@huber-recyclingtechnik.atwww.huber-recyclingtechnik.atContact person:Jürgen Huber- Cell+43 664 1257380

- AddressGeorg Bannert-Straße 21 / Top 4

A-2442 Unterwaltersdorf

- Belgium

BULK ID

info@bulkid.bewww.bulkid.beContact person:Bart VanpouckeScope:Recycling technology- Phone+32 567 15 385

- AddressOude Kassei 16

8791 Waregem

Belgium - HAAS Sales

RepresentativePatrick Szubrin

+49 2661 9865-0

Send e-mail

- Czech Republic

HAAS Recycling-Systems

sales@haas-recycling.dewww.haas-recycling.de/en- Phone+49 2661 9865-0

- Estonia

ScanBalt Crane OÜ

info@scanbaltcrane.comwww.scanbaltcrane.comContact person:Risto KippastoScope:Recycling technology- Phone+372 6024580

- AddressReti tee 7

75312 Rae vald

Estonia - HAAS Sales

RepresentativePatrick Szubrin

+49 2661 9865-0

Send e-mail

- France

SERA / Sawmill

rlegros@sera-energie.comwww.sera-bois.comContact person:Mr. Richard LegrosScope:Sawmill- Phone+33 231 634 612

- Address 159 Avenue de L'Alouette

33700 Mérignac

FRANCE - HAAS Sales

RepresentativeVolker Haas

+49 2661 9865-0

Send e-mail

- France / Recycling technology

NOREMAT

c.mazoyer@noremat.frwww.noremat.frContact person:Mr. Christophe MazoyerScope:Recycling technology- Cell+33 631 627 636

- Address166, rue Ampère

54714 Ludres Cédex

FRANCE - HAAS Sales

RepresentativePatrick Szubrin

+49 2661 9865-0

E-Mail senden

- Greece

D. F. SARANTOPOULOS S.A

gram@sarantopoulos.com.grwww.sarantopoulos.com.grContact person:Mr. SarantopoulosScope:Recycling technology- Phone+30 210 514 641 123

- AddressLenorman str. 210

104 43 ATHENS

GREECE - HAAS Sales

RepresentativeSascha Kloft

+49 2661 9865-0

Send e-mail

- Ireland

CRJ Services Ltd

enquiries@crjservices.co.ukwww.crjservices.co.ukContact person:Kiefer MorganScope:Recycling technology- Phone+44 1565 723 886 (England)

- Phone+44 1413 541 330 (Scotland)

- AddressCRJ Services

Brook House Farm

London Road

Knutsford

WA16 9LU

CRJ Services

272 Bath Street

Glasgow

G2 4JR

CRJ Services

55-59 Adelaide Street

Belfast

BT2 8FE - HAAS Sales

RepresentativeSascha Kloft

+49 2661 9865-0

Send e-mail

- Italy

VAMA ECOLOGY SRL

commerciale@vamaecology.itwww.vamaecology.itContact person:Melissa MaccaroScope:Recycling technology- Phone+39 0421310590

- AddressVia C.A. dalla Chiesa 30

30029 S. Stino di Livenza (VE)

Italy - HAAS Sales

RepresentativeSteffen Heymann

+49 171 7932677

Send e-mail

- Latvia

ScanBalt Crane OÜ

info@scanbaltcrane.comwww.scanbaltcrane.comContact person:Risto KippastoScope:Recycling technology- Phone+372 6024580

- AddressReti tee 7

75312 Rae vald

Estonia - HAAS Sales

RepresentativePatrick Szubrin

+49 2661 9865-0

Send e-mail

- Lithuania

ScanBalt Crane OÜ

Emantas@scanbaltcrane.comwww.scanbaltcrane.comContact person:Emantas Zlataravičius- Phone+37 26024580

- AddressReti tee 7

75312 Rae vald

Estonia - HAAS Sales

RepresentativePatrick Szubrin

+49 2661 9865-0

Send e-mail

- Luxembourg

HAAS Recycling-Systems

sales@haas-recycling.dewww.haas-recycling.de/en- Phone+49 2661 9865-0

- Netherlands

HAAS Recycling-Systems

sales@haas-recycling.dewww.haas-recycling.de/enScope:Recycling technology- Phone+49 2661 9865-0

- Poland

HAAS Recykling Polska Sp.o.o.

biuro@haas-recycling.plwww.haas-recycling.plContact person:Mr. Bartłomiej LewandowskiScope:Recycling technology- Phone+48 506 105 536 (Mr. Bartłomiej Lewandowski)

- Phone+48 22 114 99 95 (Mr. Michał Chołuj)

- Address03-186 Warszawa

ul. Modlińska 129 / U7 - HAAS Sales

RepresentativeSascha Kloft

+49 (0)2661 9865-0

Send e-mail

- Portugal

Dmcar Lda.

a.simoes@dmcar.ptwww.dmcar.ptContact person:Amélia SimõesScope:Recycling technology- Phone+35 123 192 95 85

- AddressEstrada Nacional 334 S N

Lugar de Vale da Mata

3450-050 Espinho MRT Portugal - HAAS Sales

RepresentativePatrick Szubrin

+49 2661 9865-0

Send e-mail

- Romania

SC INSTALIZA SRL

office@instaliza.rowww.instaliza.roContact person:Daniel Cristian MECHEREŞScope:Recycling technology- Phone+40 770 104 388

- HAAS Sales

RepresentativePatrick Szubrin

+49 2661 9865-0

E-Mail senden

- Spain

TGMM

gfullana@unoreciclaje.comwww.unoreciclaje.comContact person:Mr. Gaspar Fullana MartíScope:Recycling technology- Phone+34 971 020 031

- Cell+34 699 309129

- AddressTécnicas de Gestión y Maquinaria Medioambiental, S.L.

Gremio Toneleros 34 - Polígono Son Castelló

07009 Palma de Mallorca

Spanien - HAAS Sales

RepresentativePatrick Szubrin

+49 2661 9865-0

Send e-mail

- Sweden

TM Recycling Solutions AB

ted@tmtservice.sewww.tmtservice.seContact person:Ted AugustssonScope:Recycling technology- Phone+46 70 655 90 94

- AddressTingsryd montage

Bruksgatan 9

36240 Konga

Schweden - HAAS Sales

RepresentativeSascha Kloft

+49 (0)2661 9865-0

Send e-mail

- Switzerland

HAAS Recycling-Systems

steffen.heymann@haas-recycling.dewww.haas-recycling.deContact person:Steffen HeymannScope:Recycling technology- Phone+49 7575 209354

- Cell+49 171 7932677

- Addressfield office

Anton Gabele Strasse 7

88605 Meßkirch

Germany

- United Kingdom

CRJ Sales Ltd.

enquiries@crjservices.co.ukwww.crjservices.co.ukContact person:Ben McQuaid, DirectorScope:Recycling technology- Phone+44 1565 723 886 (England)

- Phone+44 1413 541 330 (Scotland)

- Cell+44 795 893 9955

- AddressCRJ Services

Brook House Farm

London Road

Knutsford

WA16 9LU

CRJ Services

272 Bath Street

Glasgow

G2 4JR

CRJ Services

55-59 Adelaide Street

Belfast

BT2 8FE - HAAS Sales

RepresentativeSascha Kloft

+49 2661 9865-0

Send e-mail

North America

South America

- Brazil

BRUNO Industrial Ltda.

arno.schaly@bruno.com.brwww.bruno.com.brContact person:Mr. Arno Rui SchalyScope:Recycling technology- Phone+55 49 3541 3115

- Fax+55 49 3541-3178

- AddressRod Br.282 km 340 n.° 83

Distrito Industrial

Campos Novos - SC

Zip Code 89.620-000

BRASIL - HAAS Sales

RepresentativeVolker Haas

+49 2661 9865-0

Send e-mail

- Further Countries

HAAS Recycling-Systems

sales@haas-recycling.dewww.haas-recycling.de/en- Phone+49 2661 9865-0

Australia

- Australia

CEMAC technologies Pty Ltd

info@cemactech.comwww.cemactech.comContact person:Kurt PalmerScope:Recycling technology- Phone+61 03 8400 6066

- Address39 Arbor Way

3201 Carrums Downs

Victoria

Australia - HAAS Sales

RepresentativeSascha Kloft

+49 (0)2661 9865-0

E-Mail senden

Africa

- Africa

FORESTRY Plant & Equipment

fpe@forestryplant.co.zawww.forestryplant.comContact person:Phillip HallScope:Recycling technology- Phone+27137551003

- Address18 Waterfall Avenue

Riverside Industrial Park, Nelspruit

1200 Nelspruit - HAAS Sales

RepresentativePatrick Szubrin

+49 2661 9865-0

Send e-mail

- Africa

WIS - Wood Industry Supplies CC

wis@iafrica.comwww.wis.za.comContact person:Mr. Volker BächleScope:Sawmill- Phone+27 44 533-3651-2

- Fax+27 86 600 3724

- AddressP.O. Box 245

6600 Plettenberg-Bay

South Africa ZA - HAAS Sales

RepresentativeVolker Haas

+49 2661 9865-0

Send e-mail

Asia

- Japan

Okada Aiyon Corporation

watanabe@aiyon.co.jphttp://okada-aiyon.com/Scope:Recycling technology- Phone+81665761268

- Address4-1-18, Kaigan-dori

552-0022 Minato-ku,Osaka

Osaka

Japan - HAAS Sales

RepresentativerSascha Kloft

+49 (0)2661 9865-0

Send e-mail

- Korea

Minchang Engineering & Trading

minent2015@gmail.com

Co. Ltd.Contact person:Jaemin KimScope:Recycling technology- Phone+82 317 133 604

- AddressC-620 SigmaII 164, Tancheonsang-ro, Bundang-Gu, Seongnam-Si

13631 Gyunggi-Do - HAAS Sales

RepresentativerSascha Kloft

+49 (0)2661 9865-0

Send e-mail

- Taiwan

Feng Hong Machinery

fenghonglee@fenghongmachinery.com.twwww.fenghongmachinery.com.tw/

Co. Ltd.Contact person:Ping-Feng LeeScope:Recycling technology- Phone+88 622 792 9293

- AddressNeihu Dist.

No. 216, Ankang Rd.

114 Taipei City

Taiwan - HAAS Sales

RepresentativeSascha Kloft

+49 (0)2661 9865-0

Send e-mail

- Thailand / Recyclingtech. / Sägewerk

Milestones Technology

sukhumal@milestones.co.thwww.milestones.co.th

Co. Ltd.Contact person:Mrs. Sukhumal AranyapongpaisalScope:Recycling technology / Sawmill- Phone+66 294 295026

- Address126/53 Soi Phaholyothin 32

Phaholyothin Road, Senanikhom

Chatuchak

10900 Bangkok

Thailand - HAAS Sales

RepresentativeSascha Kloft

+49 (0)2661 9865-0

Send e-mail

- Turkey

BSK GLOBAL Makina Mühendislik

info@bsk-global.com www.bsk-global.comContact person:Besmira YigitScope:Recycling technology- Phone+90 532 11 11 882

- AddressSanayi Ticaret Ve Pazarlama A.S.

Adalet Mah. Manas Blv. Folkart Towers B Blok

iÇ Kapi No: 47 B/240

Bayrakli / Izmir

Turkey